Construction budgets these days are underneath more pressure than ever. Rising material costs, tighter timelines, and higher purchaser expectations leave little room for mistakes. Among all construction substances, timber performs a critical function in both structural integrity and standard challenge cost. Even minor inaccuracies in dimension can ripple through procurement, scheduling, and coins float.

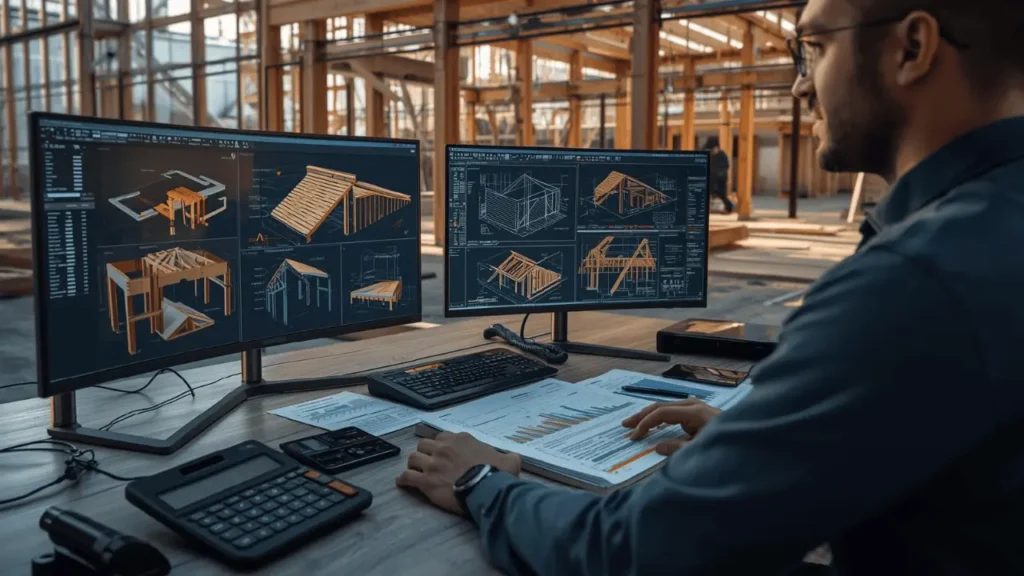

Modern production companies are moving away from rough approximations and adopting smarter, records-subsidized measurement strategies. These superior approaches are not pretty much counting substances; they’re about gaining financial clarity, enhancing predictability, and protecting margins at every stage of the task lifecycle. When wooden portions are calculated with precision, decision-making turns into quicker, dangers are cut back, and budget controls are strengthened throughout every phase of production.

Rethinking Wood Quantification in Modern Construction

Traditional wooden dimension strategies regularly depended on manual calculations, revel in-primarily based assumptions, and static drawings. While those strategies worked in less difficult tasks, they struggled to keep up with complicated designs and tight financial controls. Advanced dimension techniques introduce accuracy on the strategy planning stage, wherein financial effects are in large part determined.

By applying targeted virtual amount analysis early in the venture, teams can forecast material desires with a ways deal more confidence. A particular lumber takeoff done at this degree guarantees that buying aligns intently with actual website requirements, lowering excess inventory and minimizing last-minute orders that typically come at top-rate expenses. This stage of clarity allows venture managers to set realistic budgets in preference to padded estimates.

More importantlypresent-dayay quantification connects measurement directly to financial planning. When every beam, joist, and panel is accounted for, value projections emerge as grounded in actual statistics instead of assumptions. This shift transforms timber measurement from a technical task into a strategic economic tool.

Digital Measurement Techniques: Reducing Cost Variance

Advanced timber measurement techniques are increasingly driven with the aid of virtual workflows. Three-dimensional modeling, cloud-based total amount structures, and real-time visions permit teams to adapt fast as designs evolve. When an architect adjusts a structural element, up-to-date quantities may be generated instantly, preventing outdated numbers from driving procurement decisions.

Consider a mid-sized business task wherein timber framing represents 18% of the total fabric finances. A 7% overestimation ought to tie up tens of thousands of greenbacks in unused substances. Conversely, a 5% underestimation may result in purposeful stoppages at the same time as extra materials are sourced. Digital size tools lessen these gaps by maintaining alignment between design reason and fabric reality.

Financial manipulation improves, in addition, when measurement statistics feed without delay into fee monitoring systems. Project groups can evaluate deliberate versus real utilization, identify styles of waste, and make corrections earlier than overruns strengthen. Over time, these records build a reliable price history that strengthens destination budgeting accuracy.

Financial Oversight Through Integrated Estimating Expertise

Accurate size alone is not enough; it ought to be interpreted correctly to aid financial choices. This is where professional estimating expertise becomes crucial. When timber amount information is reviewed and verified by using a Construction estimating Company, it provides its monetary context that website online groups can depend on.

Estimators analyze how portions translate into hard work, sequencing, and supplier pricing. For instance, understanding that 12,500 board feet are required is the best part of the image. An estimator evaluates how delivery schedules, cutting waste, and nearby charge fluctuations will have an effect on the final value. This perception transforms uncooked numbers into actionable financial intelligence.

Integration among dimensions and estimating additionally supports stronger bid accuracy. Projects priced with particular wooden statistics are much less probably to suffer from margin erosion caused by neglected additives. As a result, contractors can submit a competitive bid without exposing themselves to pointless economic risk.sk

Accountability and Forecast Accuracy on the Enterprise Level

At a broader stage, advanced wooden dimension strategies guide organisation-wide monetary discipline. When standardized procedures are used throughout projects, management gains constant records for forecasting and performance analysis. This consistency makes it less difficult to identify which venture types, designs, or creation methods supply the most powerful financial outcomes.

Reliable size statistics additionally improved. Teams can trace cost variances agbacko precise layout modifications or website onliitions in place of absorbing losses without explanation. Over time, this transparency builds a subculture of non-stop development, in which instructions learned translate into tighter budgets and more predictable effects.

For growing creation corporations, this stage of management is important. As venture volume increases, small inefficiencies multiply speedily. Advanced dimension structures act as a guard, ensuring that boom no longer comes at the expense of financial balance.

Translating Measured Data Into Budget-Safe Execution

The actual fee of superior wooden dimension strategies emerges at some point of execution. Accurate quantities guide procurement timing, helping teams purchase substances while expenses are favorable and storage prices are attainable. This technique improves cash flow and decreases exposure to market volatility.

When supported with the aid of expert Construction estimating services, measured facts additionally inform trade management. If a layout revision adds three hundred square feet of structural framing, the cost impact may be calculated at once, documented without a doubt, and communicated to stakeholders. This transparency prevents disputes and protects profit margins.

On-website online efficiency improves as well. Crews paint with self-assurance when materials arrive in proper portions at the right time. Fewer interruptions suggest steadier development, lower labor inefficiencies, and more potent alignment between timetable and price range.

Read more: Dimensional 2×6 Lumber Sizes Applied in Building and Remodeling of Home

Final Thoughts

Advanced wooden dimension strategies are no longer optional in cutting-edge construction. They shape the muse of dependable economic manipulate, permitting groups to transition from reactive fee management to proactive planning. By combining specific amount analysis with expert economic interpretation, production corporations can reduce uncertainty, fortify margins, and supply projects with greater confidence.

As competition intensifies and clients demand transparency, individuals who invest in smarter measurement practices will be better positioned to be successful. Accurate information does more than inform decisions; it empowers teams to construct efficaciously, responsibly, and profitably in an increasingly complicated production landscape.

Frequently Asked Questions

1. Why is precise wooden dimension so crucial for financial control?

Because wood represents a huge portion of material charges, even small inaccuracies can lead to significant financial errors or delays.

2. How does digital equipment improve size accuracy?

They update portions automatically when designs are exchanged, reducing manual mistakes and keeping estimates aligned with current drawings.

3. Can advanced sizing reduce material waste?

Yes, accurate quantities help teams order toward real wishes, minimizing excess substances and disposal costs.

4. Does a better dimension affect assignment scheduling?

Absolutely. When materials are ordered efficiently and delivered on time, construction flows greater smoothly with fewer interruptions.

5. How do measurement facts guide economic forecasting?

It provides reliable inputs for value fashions, permitting companies to estimate expenses and cash flows with greater confidence.

6. Is a supersize useful for small projects as well?

Yes. Even smaller projects advantage from improved accuracy, as tighter budgets leave no room for pricey errors.